In the world of high-voltage electrical systems, reliability and safety are paramount. One critical component that contributes to these attributes is the feedthru insert. Among the various types of feedthru inserts available, the 15kV 200A Rotatable Feedthru Insert stands out for its innovative design and robust performance. Manufactured to meet stringent industry standards, this product is an essential part of load break connections in electrical distribution systems. This article provides an in-depth look at feedthru inserts, their functionality, and the features that make the 15kV 200A Rotatable Feedthru Insert a preferred choice in the field.

A feedthru insert is a specialized electrical connector designed to facilitate the transmission of electrical power through a bushing while ensuring safety and efficiency. These inserts are used primarily in high-voltage applications, providing a means to connect and disconnect power without interrupting the flow of electricity.

The feedthru insert serves several critical functions:

- It allows for safe load break operations.

- It provides a secure connection between the transformer and the electrical distribution system.

- It enables field installation and replacement, making maintenance and upgrades easier and more efficient.

The versatility and ease of use of feedthru inserts make them indispensable components in electrical infrastructure.

Overview of the 15kV 200A Rotatable Feedthru Insert

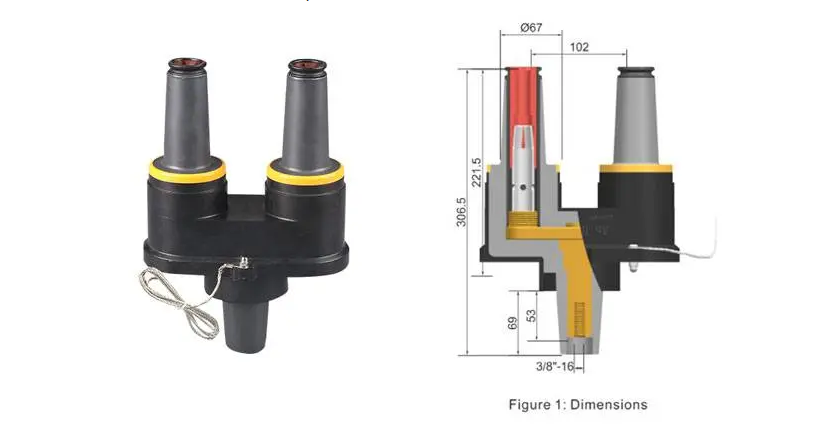

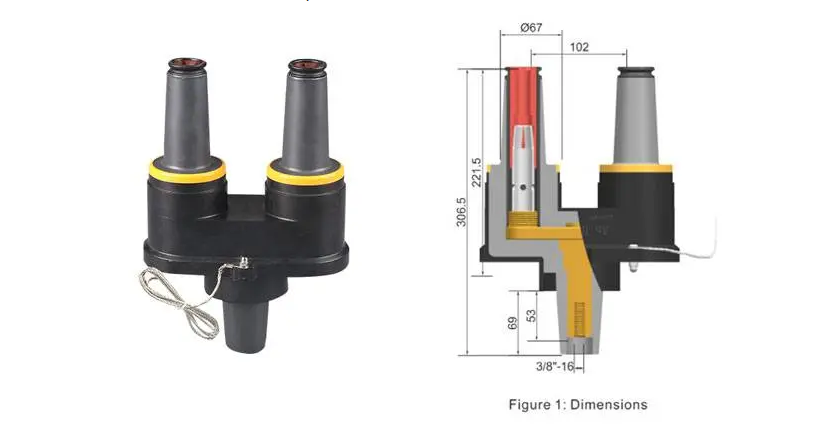

The 15kV 200A Rotatable Feedthru Insert is a high-quality product manufactured by Anhuang, a company renowned for its expertise in producing rotatable feedthru inserts that comply with IEEE Standard 386. This insert is designed to thread into a universal bushing well, providing the same functionality as an integral load break bushing. Here’s a closer look at its features and benefits:

Key Features

- High Voltage Rating: The 15kV rating signifies that this feedthru insert can safely operate in high-voltage environments, making it suitable for a wide range of electrical distribution applications.

- Current Rating: With a 200A rating, this insert can handle substantial current loads, ensuring it meets the demands of modern electrical systems.

- Rotatable Design: The rotatable feature allows for flexible installation options, enabling technicians to position the elbow connectors in the most convenient orientation for the installation site. This flexibility minimizes installation time and simplifies the maintenance process.

- Patented Current Path Design: The bushing insert employs a patented wholly current path that contains only one current transfer point within the insert itself. This design minimizes electrical resistance and improves performance reliability.

- Torque-Controlled Installation: An internal broach facilitates a positive torque-controlled installation. When used with the optional installation torque tool, it allows for precise tightening without risking damage to the bushing well stud, enhancing the overall integrity of the connection.

- Power Exclusive Latch Indicator Ring: Located on the bushing’s collar, this bright yellow ring eliminates guesswork during the load break elbow installation. It provides immediate visual feedback to determine if the elbow is properly installed on the insert, enhancing safety and reducing installation errors.

- Molded Construction: The feedthru insert is molded using high-quality sulfur-cured insulation and semi-conductive EPDM rubber. This ensures durability and resilience against environmental factors, allowing for reliable operation even in harsh conditions.

- Submersible Connection: When mated with comparably rated components, the bushing insert provides a fully shielded and submersible connection, allowing for load break operations in various settings, including underground installations.

Compliance and Interchangeability

The Compliance and Interchangeability section discusses two key aspects of the 15kV 200A Rotatable Feedthru Insert that enhance its value and usability in high-voltage electrical systems: adherence to industry standards and the ability to replace or work alongside similar products from other manufacturers.

1. Compliance with IEEE Standard 386

- Definition of Compliance: Compliance refers to the ability of a product to meet specific standards and regulations set by authoritative organizations. In this case, the 15kV 200A Rotatable Feedthru Insert complies with IEEE Standard 386.

- Significance of IEEE Standard 386: This standard provides guidelines for the design, testing, and performance of connectors and bushings used in electrical distribution systems. By meeting these requirements, the feedthru insert ensures that it is safe, reliable, and suitable for high-voltage applications. Compliance is crucial for ensuring that the insert can operate effectively within established safety parameters and performance metrics.

- Definition of Interchangeability: Interchangeability refers to the ability of a product to be replaced or used in place of another product without requiring major modifications or adjustments. This means that the 15kV 200A Rotatable Feedthru Insert can easily substitute for similar products offered by other manufacturers.

- Benefits of Interchangeability:

- Flexibility in Upgrades: Utilities and contractors can replace existing feedthru inserts with Anhuang’s product without overhauling the entire system. This flexibility allows for quick upgrades to newer technology or improvements in performance without incurring significant costs or downtime.

- Wider Compatibility: Since the insert can work with various bushing wells and elbow connectors from different manufacturers, it provides users with a broader selection of components to choose from, promoting flexibility in system design and maintenance.

2. Interchangeability with Competitor Products

Importance of Bushing Inserts in Load Break Connections

Bushing inserts, such as the 15kV 200A Rotatable Feedthru Insert, are critical components of load break connections in high-voltage electrical systems. Their importance can be summarized in the following points:

- Safety: Bushing inserts enable safe connection and disconnection of electrical loads, reducing the risk of electrical arcing and enhancing overall safety during maintenance operations.

- Efficiency: With a streamlined installation process, bushing inserts allow for quick field installations and replacements, minimizing downtime in electrical distribution systems.

- Reliability: The robust design of these inserts, including features such as the patented current path and high-quality materials, ensures reliable performance over time, even under demanding conditions.

- Versatility: Bushing inserts can be utilized in various applications, including substations, distribution networks, and industrial settings, making them versatile components in electrical infrastructure.

- Cost-Effectiveness: By enabling easy installation and maintenance, bushing inserts can reduce labor costs and overall operational expenses for utility companies and contractors.

Installation and Maintenance Considerations

When installing the 15kV 200A Rotatable Feedthru Insert, several best practices should be followed to ensure optimal performance:

- Use Proper Tools: Employ the optional installation torque tool to tighten the bushing insert properly. This tool helps achieve the necessary torque without risking damage to the bushing well.

- Visual Inspection: Before installation, perform a visual inspection of the bushing well and insert to check for any damage or wear that could affect performance.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions and guidelines for installation and maintenance to ensure compliance with safety standards.

- Regular Maintenance: Implement a regular maintenance schedule to inspect the feedthru inserts and associated components for signs of wear or damage, ensuring continued reliability and performance.

Conclusion

The feedthru insert, particularly the 15kV 200A Rotatable Feedthru Insert, is a vital component in high-voltage electrical systems, providing safety, efficiency, and reliability. With its advanced design and robust construction, this insert plays a crucial role in load break connections, enabling safe power distribution in various applications.

Anhuang‘s commitment to high-quality manufacturing and adherence to industry standards ensures that their feedthru inserts are suitable for modern electrical infrastructure. As electrical systems continue to evolve, the importance of reliable components like the feedthru insert will only grow, making them essential for maintaining the integrity and safety of power distribution networks.